Small strain plasticity¶

A framework for the approximation of plasticity models in GetFEM++. See in src/getfem_plasticity.cc and interface/src/gf_model_set.cc for the brick implementation and to extend the implementation to new plasticity models.

Theoretical background¶

We present a short introduction to small strain plasticity. We refer mainly to [SI-HU1998] and [SO-PE-OW2008] for a more detailed presentation.

Additive decomposition of the small strain tensor¶

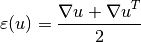

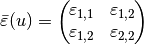

Let  be the reference configuration of a deformable body and

be the reference configuration of a deformable body and  be the displacement field. Small strain plasticity is based on the additive decomposition of the small strain tensor

be the displacement field. Small strain plasticity is based on the additive decomposition of the small strain tensor  in

in

where  is the elastic part of the strain tensor and

is the elastic part of the strain tensor and  the plastic one.

the plastic one.

Internal variables, free energy potential and elastic law¶

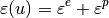

We consider

a vector field of  strain type internal variables (

strain type internal variables ( if no internal variables are considered). We consider also a free energy potential

if no internal variables are considered). We consider also a free energy potential

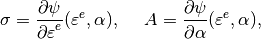

such that corresponding stress type variables are determined by

where  is the Cauchy stress tensor and

is the Cauchy stress tensor and  the stress type internal variables. The plastic dissipation is given by

the stress type internal variables. The plastic dissipation is given by

In the standard cases,  is decomposed into

is decomposed into

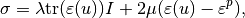

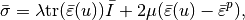

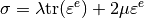

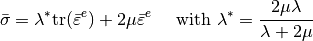

In the case of linearized elasticity, one has  where

where  is the fourth order elasticity tensor. For isotropic linearized elasticity this expression reduces to

is the fourth order elasticity tensor. For isotropic linearized elasticity this expression reduces to  where

where  is the shear modulus and

is the shear modulus and  is the bulk modulus.

is the bulk modulus.

Plastic potential, yield function and plastic flow rule¶

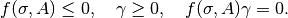

Plastic yielding is supposed to occur when the stress attains a critical value. This limit is determined by a yield function  and the condition

and the condition

The surface  is the yield surface where the plastic deformation may occur.

is the yield surface where the plastic deformation may occur.

Let us also consider the plastic potential  , (convex with respect to its both variables) which determines the plastic flow direction in the sense that the flow rule is defined as

, (convex with respect to its both variables) which determines the plastic flow direction in the sense that the flow rule is defined as

with the additional complementarity condition

The variable  is called the plastic multiplier. Note that when

is called the plastic multiplier. Note that when  are not differentiable, subdifferentials have to be used. Associated plasticity corresponds to the choice

are not differentiable, subdifferentials have to be used. Associated plasticity corresponds to the choice  .

.

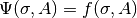

Initial boundary value problem¶

The weak formulation of a dynamic elastoplastic problem can be written, for an arbitrary kinematically admissible test function  , as follows:

, as follows:

for  being initial values and

being initial values and  and

and  being prescribed forces in the interior of domain

being prescribed forces in the interior of domain  and on the part of the boundary

and on the part of the boundary  .

.

Note that plasticity models are often applied on quasi-static problems which correspond to the term  being neglected.

being neglected.

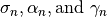

Given a time step  , from time

, from time  to

to  , we will denote in the sequel

, we will denote in the sequel  the approximations at time

the approximations at time  of

of  respectively. These approximations correspond to the chosen time integration scheme (for instance one of the proposed schemes in The model tools for the integration of transient problems) which can be different than the time integration scheme used for the integration of the flow rule (see below).

respectively. These approximations correspond to the chosen time integration scheme (for instance one of the proposed schemes in The model tools for the integration of transient problems) which can be different than the time integration scheme used for the integration of the flow rule (see below).

Flow rule integration¶

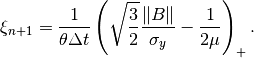

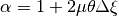

The plastic flow rule has to be integrated with its own time integration scheme. Among standards schemes, the backward Euler scheme, the  -scheme (or generalized trapezoidal rule) and the generalized mid-point scheme are the most commonly used in that context. We make here the choice of the

-scheme (or generalized trapezoidal rule) and the generalized mid-point scheme are the most commonly used in that context. We make here the choice of the  -scheme (

-scheme ( corresponds to the backward Euler scheme as a special case).

corresponds to the backward Euler scheme as a special case).

Let  be the displacement at the considered time step and

be the displacement at the considered time step and  at the previous one.

at the previous one.

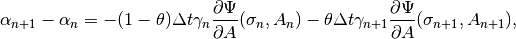

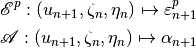

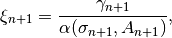

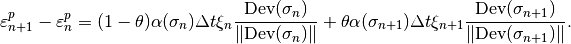

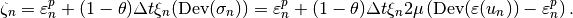

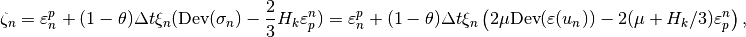

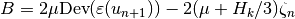

The  -scheme for the integration of the plastic flow rules reads as

-scheme for the integration of the plastic flow rules reads as

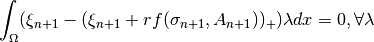

(1)

(2)

with the complementary condition

where  is the parameter of the

is the parameter of the  -scheme. We exclude

-scheme. We exclude  because we will not consider explicit integration of plasticity. Let us recall that

because we will not consider explicit integration of plasticity. Let us recall that  corresponds to the backward Euler scheme and

corresponds to the backward Euler scheme and  to the Crank-Nicolson scheme (or trapezoidal rule) which is a second order consistent scheme. Note that the complementarity condition for the quantities at time step

to the Crank-Nicolson scheme (or trapezoidal rule) which is a second order consistent scheme. Note that the complementarity condition for the quantities at time step  is prescribed at the previous time step (

is prescribed at the previous time step ( are supposed to be already determined).

are supposed to be already determined).

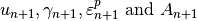

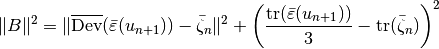

A solution would be to solve the whole problem with all the unknows, that is  . This is of course possible but would be a rather expensive strategy because of the resulting high number of degrees of freedom. A classical strategy (the return mapping one for instance, see [SO-PE-OW2008] or the closest point projection one) consist in integrating locally the plastic flow on each Gauss point of the considered integration method separately, or more precisely to consider on each Gauss point the maps

. This is of course possible but would be a rather expensive strategy because of the resulting high number of degrees of freedom. A classical strategy (the return mapping one for instance, see [SO-PE-OW2008] or the closest point projection one) consist in integrating locally the plastic flow on each Gauss point of the considered integration method separately, or more precisely to consider on each Gauss point the maps

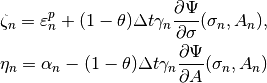

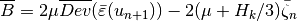

with  the right hand side of equations (1), (2), i.e.

the right hand side of equations (1), (2), i.e.

This means in particular that  is the solution to equations (1) and (2). Both these maps and their tangent moduli (usually called consistent tangent moduli) are then used in the global solve of the problem with a Newton method and for

is the solution to equations (1) and (2). Both these maps and their tangent moduli (usually called consistent tangent moduli) are then used in the global solve of the problem with a Newton method and for  the unique remaining variable. The advantage of the return mapping strategy is that the unique variable of the global solve is the displacement

the unique remaining variable. The advantage of the return mapping strategy is that the unique variable of the global solve is the displacement  . A nonlinear solve on each Gauss point is often necessary which is usualy performed with a local Newton method.

. A nonlinear solve on each Gauss point is often necessary which is usualy performed with a local Newton method.

In GetFEM++ we propose both the return mapping strategy and also an alternative strategy developped below which is mainly inspired from [PO-NI2016], [SE-PO-WO2015] and [HA-WO2009] and allow more simple tangent moduli. It consists in keeping (a multiple of)  as an additional unknown with respect to

as an additional unknown with respect to  . As we will see, this will allow a more generic treatment of the yield functions, the price for the simplicity being this additional unknown scalar field.

. As we will see, this will allow a more generic treatment of the yield functions, the price for the simplicity being this additional unknown scalar field.

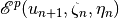

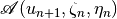

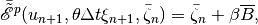

First, we consider an additional (and optional) given function  whose interest will appear later on (it will allow simple local inverses) and the new unknown scalar field

whose interest will appear later on (it will allow simple local inverses) and the new unknown scalar field

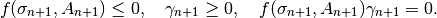

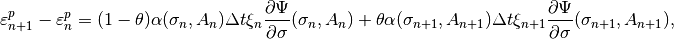

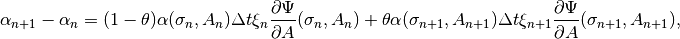

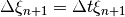

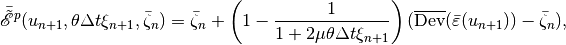

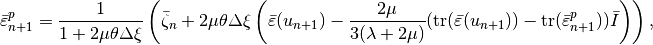

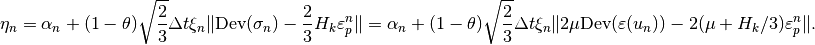

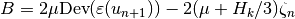

so that our two main unknows are now  . The discretized plastic flow rule integration now reads:

. The discretized plastic flow rule integration now reads:

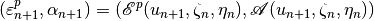

(3)

(4)

(5)

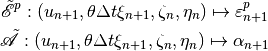

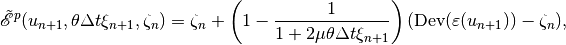

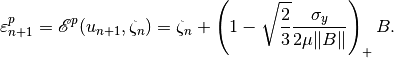

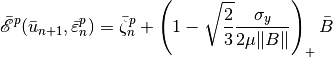

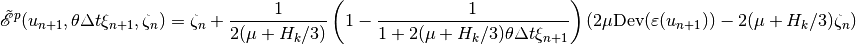

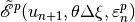

For  be given, we define the two maps

be given, we define the two maps

where the pair  is the solution to equations (3), (4) (without the consideration of (5)). We will see later, that, at least for simple isotropic plastic flow rules, these maps have a simple expression, even sometimes a linear one with respect to

is the solution to equations (3), (4) (without the consideration of (5)). We will see later, that, at least for simple isotropic plastic flow rules, these maps have a simple expression, even sometimes a linear one with respect to  .

.

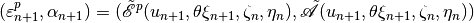

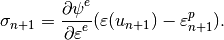

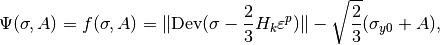

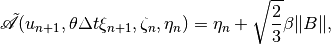

Still  be given the stress

be given the stress  reads

reads

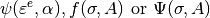

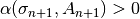

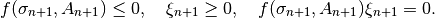

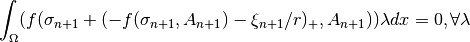

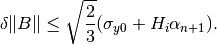

The complementarity equation (5) is then prescribed with the use of a well chosen complementarity function, as in [HA-WO2009] for  such as:

such as:

or

NOTE : The notation  is often used in the litterature. The choice here is to preserve the distinction between the two quantities, mainly because ot the possible use of adaptative time step : when the time step is changing, the value

is often used in the litterature. The choice here is to preserve the distinction between the two quantities, mainly because ot the possible use of adaptative time step : when the time step is changing, the value  has to be multiplied by the new time step, so that it is preferable to store

has to be multiplied by the new time step, so that it is preferable to store  instead of

instead of  when using the

when using the  -scheme.

-scheme.

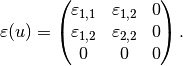

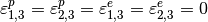

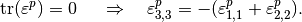

Plane strain approximation¶

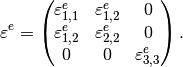

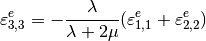

A plane strain approximation is a 2D problem which corresponds to the deformation of a long cylindrical object where the strain in the length direction (assumed to be along the  axis) is considered small compared to the ones in the other directions and is neglected. It result in a plane strain tensor of the form

axis) is considered small compared to the ones in the other directions and is neglected. It result in a plane strain tensor of the form

We denote

the non neglected components of the strain tensor. In the decomposition of plastic and elastic part of the strain tensor, we assume

and

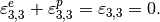

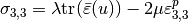

The adaptation to the plane strain approximation to plastic model is most of the time an easy task. An isotropic linearized elastic response reads

and thus

The nonzero  component of the stress tensor is given by

component of the stress tensor is given by

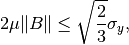

Note that in the common case where isochoric plastic strain is assumed, one has

Plane stress approximation¶

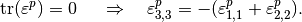

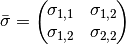

The plane stress approximation describe generally the 2D membrane deformation of a thin plate. It consist in prescribing the stress tensor to have only in-plane nonzero components, i.e.

We will still denote

the in-plane components of the stress tensor. For elastoplasticity, it consists generally to apply the 2D plastic flow rule, prescribing the out-plane components of the stress tensor to be zero with the additionnal variables  ,

,  ,

,  being unknown (see for instance [SO-PE-OW2008]).

being unknown (see for instance [SO-PE-OW2008]).

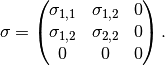

For an isotropic linearized elastic response, one has  such that

such that

with

so that

(6)

Moreover

(7)

Note that in the case where isochoric plastic strain is assumed, one still has

Some classical laws¶

Tresca :  where

where  spectral radius of the Cauchy stress tensor and

spectral radius of the Cauchy stress tensor and  the uniaxial yield stress (which may depend on some hardening internal variables).

the uniaxial yield stress (which may depend on some hardening internal variables).

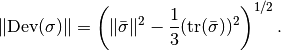

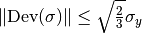

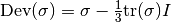

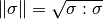

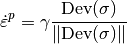

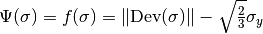

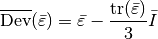

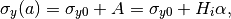

Von Mises :  where

where

the deviatoric part of

the deviatoric part of  and

and  .

.

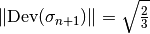

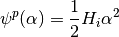

Perfect isotropic associated elastoplasticity with Von-Mises criterion (Prandl-Reuss model)¶

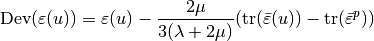

There is no internal variables and we consider an isotropic elastic response. The flow rule reads

This corresponds to  .

.

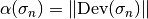

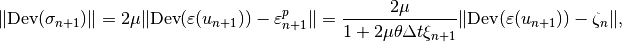

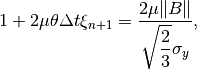

The  -scheme for the integration of the plastic flow rule reads:

-scheme for the integration of the plastic flow rule reads:

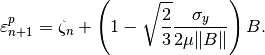

Choosing the factor  and still with

and still with  this gives the equation

this gives the equation

Since  this directly gives:

this directly gives:

which is a linear expression with respect to  (but not with respect to

(but not with respect to  ).

).

Moreover,  is defined by

is defined by

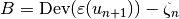

Elimination of the multiplier (for the return mapping approach)

One has

Thus, denoting  , either

, either

and  , i.e. we are in the elastic case, or

, i.e. we are in the elastic case, or  and one obtains

and one obtains

and thus

The two options can be summarized by

The multiplier  (needed for the

(needed for the  -scheme for

-scheme for  ) is given by

) is given by

Plane strain approximation

The plane strain approximation has the same expression replacing the 3D strain tensors by the in-plane ones  and

and  .

.

where  is the 2D restriction of the 3D deviator.

is the 2D restriction of the 3D deviator.

Moreover, for the yield condition,

And for the elimination of the multiplier,

with  and

and  .

.

Plane stress approximation

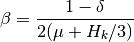

For plane stress approximation, using (6) we deduce from the expression of the 3D case

since  . Of course, this relation still has to be inverted. Denoting

. Of course, this relation still has to be inverted. Denoting  ,

,  and

and  one obtains

one obtains

Moreover, for the yield condition, expression (7) can be used.

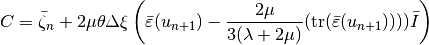

Isotropic elastoplasticity with linear isotropic and kinematic hardening and Von-Mises criterion¶

We consider an isotropic elastic reponse and the internal variable  being the accumulated plastic strain which satisfies

being the accumulated plastic strain which satisfies

For  the isotropic hardening modulus, the linear hardening consists in

the isotropic hardening modulus, the linear hardening consists in

i.e.  and a uniaxial yield stress defined by

and a uniaxial yield stress defined by

for  the initial uniaxial yield stress. The yield function (and plastic potential since this is an associated plastic model) can be defined by

the initial uniaxial yield stress. The yield function (and plastic potential since this is an associated plastic model) can be defined by

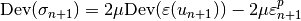

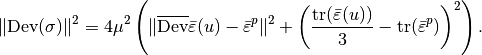

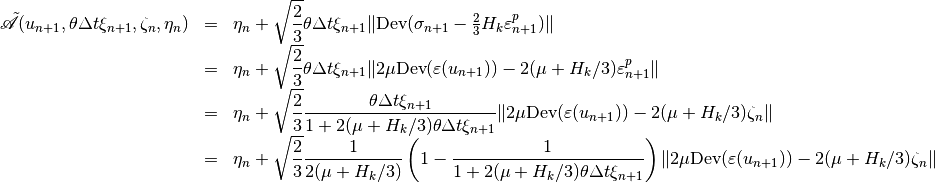

where  is the kinematic hardening modulus. The same computation as in the previous section leads to

is the kinematic hardening modulus. The same computation as in the previous section leads to

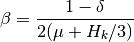

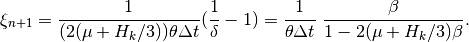

where  and

and  are defined by

are defined by

Note that the isotropic hardening modulus do not intervene in  but only in

but only in  .

.

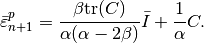

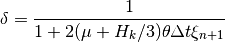

Elimination of the multiplier (for the return mapping approach)

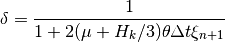

Denoting  ,

,  and

and  the expression for

the expression for  and

and  becomes

becomes

(8)

and the plastic constraint

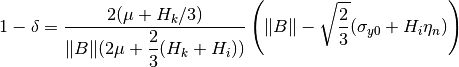

Thus, either we are in the elastic case, i.e.  and

and

or we are in the plastic case and  ,

,  and

and  solves the equation

solves the equation

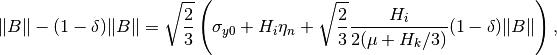

which leads to

The two cases can be summarized by

which directly gives  and

and  thanks to (8). The multiplier

thanks to (8). The multiplier  being given by

being given by

Plane strain approximation

Still denoting  ,

,  ,

,  and

and  its in-plane part, one has

its in-plane part, one has

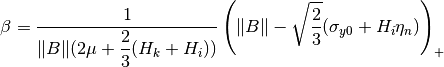

with

The yield condition still reads

and for the elimination of the multiplier,  has the same expression as in the previous section adapting the value of

has the same expression as in the previous section adapting the value of  . The expressions of

. The expressions of  and

and  have to be adpated accoringly.

have to be adpated accoringly.

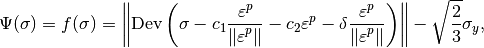

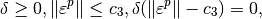

Souza-Auricchio elastoplasticity law (for shape memory alloys)¶

See for instance [GR-ST2015] for the justification of the construction of this flow rule. A Von-Mises stress criterion together with an isotropic elastic response, no internal variables and a special type of kinematic hardening is considered with a constraint  . The plastic potential and yield function have the form

. The plastic potential and yield function have the form

with the complementarity condition

where  are some physical parameters. Note that

are some physical parameters. Note that  has to be understood to be the whole unit ball for

has to be understood to be the whole unit ball for  .

.

to be done ...

Elasto-plasticity bricks¶

See the test programs tests/plasticity.cc, interface/tests/matlab/demo_plasticity.m, interface/tests/matlab/demo_plasticity.py and in contrib/test_plasticity.

Generic brick¶

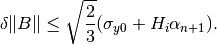

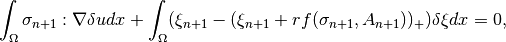

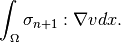

There are two versions of the generic brick. A first one when the plastic multiplier is kept as a variable of the problem where the added term is of the form:

with  having a specific value chosen by the brick (in terms of the elasticity coefficients), and when the return mapping strategy is selected (plastic multiplier is just a data), just the added term:

having a specific value chosen by the brick (in terms of the elasticity coefficients), and when the return mapping strategy is selected (plastic multiplier is just a data), just the added term:

The function which adds the brick to a model md is

getfem::add_small_strain_elastoplasticity_brick

(md, mim, lawname, unknowns_type,

const std::vector<std::string> &varnames,

const std::vector<std::string> ¶ms, region = size_type(-1));

where lawname is the name of an implemented plastic law, unknowns_type indicates the choice between a discretization where the plastic multiplier is an unknown of the problem or (return mapping approach) just a data of the model stored for the next iteration. Remember that in both cases, a multiplier is stored anyway. varnames is a set of variable and data names with length which may depend on the plastic law (at least the displacement, the plastic multiplier and the plastic strain). params is a list of expressions for the parameters (at least elastic coefficients and the yield stress). These expressions can be some data names (or even variable names) of the model but can also be any scalar valid expression of the weak form language (such as “1/2”, “2+sin(X[0])”, “1+Norm(v)” ...). The last two parameters optionally provided in params are the theta parameter of the theta-scheme (generalized trapezoidal rule) used for the plastic strain integration and the time-step`dt`. The default value for theta if omitted is 1, which corresponds to the classical Backward Euler scheme which is first order consistent. theta=1/2 corresponds to the Crank-Nicolson scheme (trapezoidal rule) which is second order consistent. Any value between 1/2 and 1 should be a valid value. The default value of dt is ‘timestep’ which simply indicates the time step defined in the model (by md.set_time_step(dt)). Alternatively it can be any expression (data name, constant value ...). The time step can be altered from one iteration to the next one. region is a mesh region.

The available plasticity laws are:

- “Prandtl Reuss” (or “isotropic perfect plasticity”). Isotropic elasto-plasticity with no hardening. The variables are the displacement, the plastic multiplier and the plastic strain. The displacement should be a variable and have a corresponding data having the same name preceded by “Previous_” corresponding to the displacement at the previous time step (typically “u” and “Previous_u”). The plastic multiplier should also have two versions (typically “xi” and “Previous_xi”) the first one being defined as data if unknowns_type = DISPLACEMENT_ONLY or as a variable if unknowns_type = DISPLACEMENT_AND_PLASTIC_MULTIPLIER. The plastic strain should represent a n x n data tensor field stored on mesh_fem or (preferably) on an im_data (corresponding to mim). The data are the first Lame coefficient, the second one (shear modulus) and the uniaxial yield stress. IMPORTANT: Note that this law implements the 3D expressions. If it is used in 2D, the expressions are just transposed to the 2D. For the plane strain approximation, see below.

- “plane strain Prandtl Reuss” (or “plane strain isotropic perfect plasticity”) The same law as the previous one but adapted to the plane strain approximation. Can only be used in 2D.

- “Prandtl Reuss linear hardening” (or “isotropic plasticity linear hardening”). Isotropic elasto-plasticity with linear isotropic and kinematic hardening. An additional variable compared to “Prandtl Reuss” law: the accumulated plastic strain. Similarly to the plastic strain, it is only stored at the end of the time step, so a simple data is required (preferably on an im_data). Two additional parameters: the kinematic hardening modulus and the isotropic one. 3D expressions only.

- “plane strain Prandtl Reuss linear hardening” (or “plane strain isotropic plasticity linear hardening”). The same law as the previous one but adapted to the plane strain approximation. Can only be used in 2D.

IMPORTANT : remember that small_strain_elastoplasticity_next_iter has to be called at the end of each time step, before the next one (and before any post-treatment : this sets the value of the plastic strain and plastic multiplier).

Additionaly, the following function allow to pass from a time step to another for the small strain plastic brick:

getfem::small_strain_elastoplasticity_next_iter

(md, mim, lawname, unknowns_type,

const std::vector<std::string> &varnames,

const std::vector<std::string> ¶ms, region = size_type(-1));

The parameters have to be exactly the same as the ones of the add_small_strain_elastoplasticity_brick, so see the documentation of this function for any explanations. Basically, this brick computes the plastic strain and the plastic multiplier and stores them for the next step. Additionaly, it copies the computed displacement to the data that stores the displacement of the previous time step (typically “u” to “Previous_u”). It has to be called before any use of compute_small_strain_elastoplasticity_Von_Mises.

The function

getfem::compute_small_strain_elastoplasticity_Von_Mises

(md, mim, lawname, unknowns_type,

const std::vector<std::string> &varnames,

const std::vector<std::string> ¶ms,

const mesh_fem &mf_vm, model_real_plain_vector &VM,

region = size_type(-1));

computes the Von Mises stress field with respect to a small strain elastoplasticity term, approximated on mf_vm, and stores the result into VM. All other parameters have to be exactly the same as for add_small_strain_elastoplasticity_brick. Remember that small_strain_elastoplasticity_next_iter has to be called before any call of this function.

A specific brick based on the low-level generic assembly for perfect plasticity¶

This is an previous version of a elastoplasticity brick which is restricted to isotropic perfect plasticity and is based on the low-level generic assembly. Its specificity which could be interesting for testing is that the flow rule is integrated on finite element nodes (not on Gauss points).

The function adding this brick to a model is:

getfem::add_elastoplasticity_brick

(md, mim, ACP, varname, previous_varname, datalambda, datamu, datathreshold, datasigma, region);

- where:

- varname represents the main displacement unknown on which the brick is added (u).

- previous_varname is the displacement at the previous time step.

- datalambda and datamu are the data corresponding to the Lame coefficients.

- datathreshold represents the plastic threshold of the studied material.

- datasigma represents the stress constraint values supported by the material. It should be composed of 2 iterates for the time scheme needed for the Newton algorithm used. Note that the finite element method on which datasigma is defined should be able to represent the derivative of varname.

- ACP corresponds to the type of projection to be used. It has an abstract_constraints_projection type and for the moment, only exists the VM_projection corresponding to the Von Mises one.

Be careful: datalambda, datamu and datathreshold could be constants or described on the same finite element method.

This function assembles the tangent matrix and the right hand side vector which will be solved using a Newton algorithm.

Additionaly, The function:

getfem::elastoplasticity_next_iter

(md, mim, varname, previous_varname, ACP, datalambda, datamu, datathreshold, datasigma);

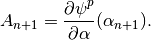

computes the new stress constraint values supported by the material after a load or an unload (once a solve has been done earlier) and upload the variables varname and datasigma as follows:

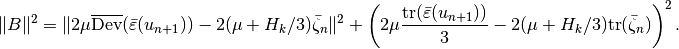

Then,  and

and  contains the new values computed and one can restart the process.

contains the new values computed and one can restart the process.

The function:

getfem::compute_elastoplasticity_Von_Mises_or_Tresca

(md, datasigma, mf_vm, VM, tresca=false);

computes the Von Mises (or Tresca if tresca = true) criterion on the stress tensor stored in datasigma . The stress is evaluated on the mesh_fem mf_vm and stored into the vector VM. Of course, this function can be used if and only if the previous function elastoplasticity_next_iter has been called earlier.

The function:

getfem::compute_plastic_part

(md, mim, mf_pl, varname, previous_varname, ACP, datalambda, datamu, datathreshold, datasigma, Plast);

computes on mf_pl the plastic part of the material, that could appear after a load and an unload, into the vector Plast.

Note that datasigma should be the vector containing the new stress constraint values, i.e. after a load or an unload of the material.